Browse our latest products

Featured products

-

12 oz Tumbler

Regular price $20.00 CADRegular price -

20oz Tumbler

Regular price $25.00 CADRegular price -

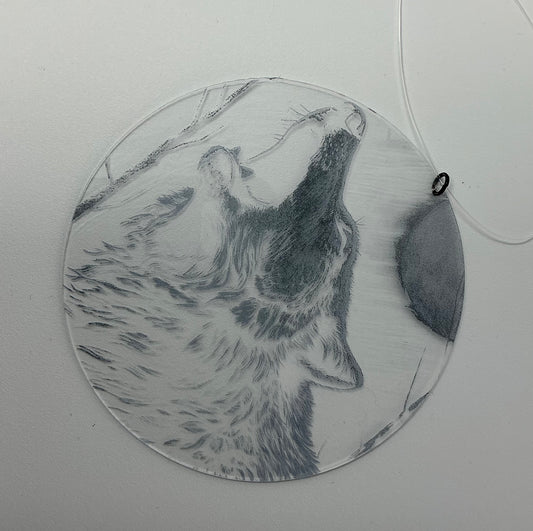

Acrylic Sun Catcher

Regular price $8.00 CADRegular price -

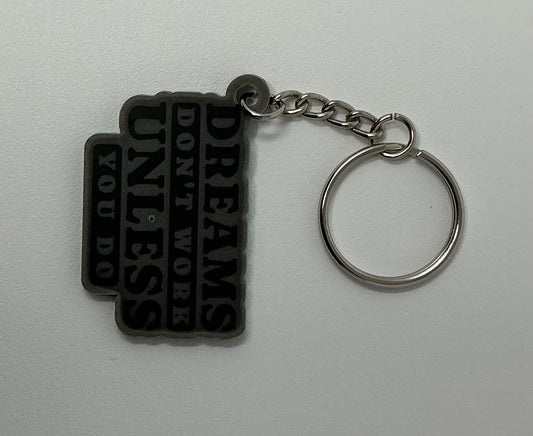

Black Acrylic Key chains

Regular price $5.00 CADRegular price -

Circle Wall Mount Magnet Board

Regular price $85.00 CADRegular price -

Corn Hole Boards

Regular price $350.00 CADRegular price -

Dad’s barbecue utensil set

Regular price $45.00 CADRegular price -

Dipped hard hats

Regular price $150.00 CADRegular price